A lobby is the building’s first threshold. It sets the tone for everything that follows, from circulation and scale to the tactile moments of arrival. When metal is specified here, it cannot behave like decoration. It has to hold light, wear, and proportion with the same discipline.

Traditional metal fabrication can introduce weight, seams, corrosion risk, and compromises around complex geometry and installation. Modulux is often specified when the design intent calls for a continuous metal language across focal walls, reception elements, columns, and elevator surrounds, without letting construction constraints dictate the visual outcome.

In lobby environments, consistency is the true luxury. The finish needs to read as one decision across different elements, trades, and lighting conditions. Modulux supports this with sample led alignment, controlled sheen, and repeatable finishing logic, so walls, portals, and touchpoints remain coherent from the first mockup to the final install.

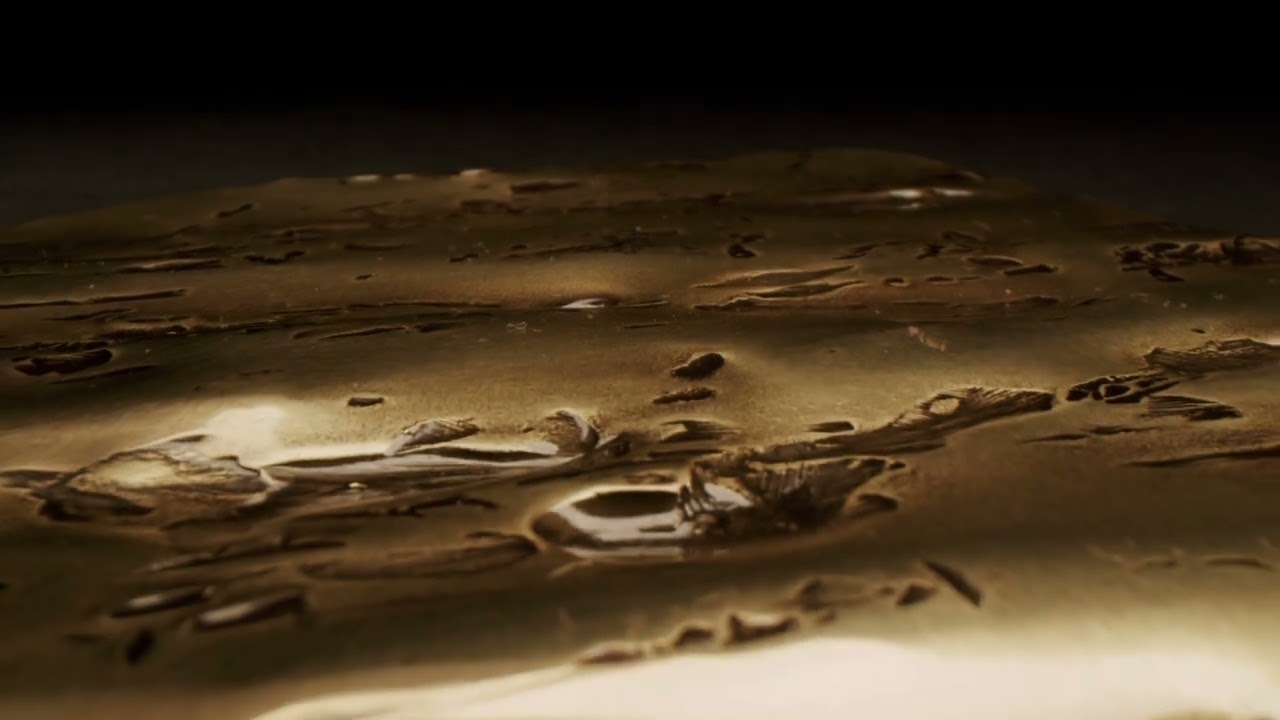

Lobby metals should be specified by light behavior, not by generic color names. Establish where daylight grazes surfaces, where artificial lighting creates hotspots, and where reflections must be softened. Define the finish intent as a combination of tone, texture, and sheen control, then anchor decisions to a physical reference sample. This allows MetaliQ Liquid Metal Coatings, TruMetal Arc Wire Coatings, Finishes on Traditional Metals, or LuxCoat Wet Coatings to be selected as the most buildable path while holding one visual language across the entry sequence.

Lobbies often combine joinery, wall construction, and metalwork in one view. The design advantage comes from choosing a finishing approach that reduces fragmentation. Where sheet metal would force breaks and trims, a coating approach can support calmer planes and clearer edges. Where real metal fabrication is already required, finishing discipline keeps parts aligned despite different fabricators or phased deliveries. The goal is coordination that protects geometry, not a finish that fights it.

Surface preparation is what makes metal feel architectural. Substrates must be stable, flat, and suitable for the selected system, with corners and reveals prepared as intentional geometry rather than afterthoughts. Plan for wrapped corners, crisp lines, and consistent transitions, especially on reception desks and column cladding where close viewing is constant. Preparation also defines how seams are minimized and how reflectivity remains even under grazing light.

A lobby finish succeeds when it is refined, not merely applied. Brushing direction, polishing level, and patina layering should be controlled to avoid visual noise across large surfaces. Sealing is project specific and should reflect the environment and touch frequency, especially on reception fronts and elevator surrounds. Modulux workflows rely on reference samples, controlled refinement, and sealing selection so the finish remains serviceable and visually consistent over time.

Custom reception desks are suitable for a wide range of applications:

Creating an impressive and luxurious first impression that defines the hospitality experience.

Creating an impressive and luxurious first impression that defines the hospitality experience.

Creating an impressive and luxurious first impression that defines the hospitality experience.

Define which lobby elements carry the metal language and which remain supporting materials. Typical targets include focal walls, reception desks, column cladding, waiting area features, and elevator facades. Confirm viewing distances and lighting conditions for each element. Then decide where a seamless coating direction is preferred, where an arc wire metal layer is more appropriate, and where finishing directly on real metal is required for fabricated components.

Sampling should be treated as a specification tool, not a visual suggestion. Establish one approved reference that defines tone, texture, and sheen, then use it as the control point for all elements. Review samples under the actual lobby lighting when possible. Lock brushing direction, patina character, and reflectivity targets before production starts, especially when multiple trades produce adjacent parts.

Confirm the substrate list early and validate it against the selected finish path. MetaliQ Liquid Metal Coatings can be used on prepared substrates such as MDF, wood, composites, stone, and existing metal where appropriate. Finishes on Traditional Metals require real metal substrates such as brass, bronze, copper, steel, or stainless. For TruMetal Arc Wire Coatings and LuxCoat Wet Coatings, substrate suitability and preparation level should be confirmed during sampling, with project specific preparation steps documented.

Lobby finishes should be specified with maintenance behavior in mind. Define cleaning expectations, touch frequency, and any exposure risks, then align sealing and care guidance accordingly. Routine cleaning should remain gentle and non abrasive, with escalations handled through controlled advice rather than improvised chemicals. Where a dedicated cleaning product is specified for liquid metal surfaces, include it in the handover plan so the finish is preserved with repeatable care.

In lobby environments, finish selection begins with the element map, then moves to sample alignment under real lighting. Surfaces are prepared to support clean edges and stable reflectivity, with corners and reveals treated as part of the geometry. MetaliQ Liquid Metal Coatings are often chosen when a seamless metal surface is required across complex forms. TruMetal Arc Wire Coatings can be specified where a real metal layer is needed for durability and then refined into an architectural finish. Finishes on Traditional Metals serve fabricated brass, bronze, copper, steel, or stainless elements that require controlled brushing, patina, and sealing. LuxCoat Wet Coatings support disciplined color and sheen consistency where a wet coating build is the most practical route. Sealing and sheen control remain project specific.

Substrate suitability is confirmed during sampling and depends on the chosen system. MetaliQ can be applied to prepared substrates such as MDF, wood, composites, stone, and existing metal where appropriate. Finishes on Traditional Metals require real metal substrates. Share your substrate list early for verification.

Edges are treated as design geometry, not an afterthought. Preparation focuses on stability and uniformity so corners do not telegraph inconsistencies in sheen or texture. Wrapped corners and crisp reveals are planned at the detailing stage and verified through samples before production.

Suitability depends on exposure conditions and the specified protection strategy. Interior lobbies typically prioritize touch and cleanability. For exterior or semi exterior entry zones, confirm environmental factors and select a project specific sealing and maintenance plan to match the conditions.

Routine care should be gentle. Clean with a damp cloth, avoid strong or abrasive materials, and keep cleaning methods consistent across the project. If a dedicated cleaning product is specified for liquid metal surfaces, include it in the maintenance routine for predictable preservation.

Plan repair logic during sampling. Define acceptable touch up visibility zones, keep reference samples for future matching, and document the approved tone and sheen. For fabricated metal parts, controlled refinishing and resealing may be preferable to spot repairs, depending on the finish direction.

Timeline depends on scope, the number of elements, and sampling cycles. Establish a sampling and approval window first, then sequence preparation, finishing, and sealing to match site readiness. Share your installation dates so production can be aligned to phased delivery if needed.

Project references are available upon request. Share your lobby scope, target finishes, and substrate list, and Modulux can provide relevant examples with comparable lighting conditions, geometry, and touch zones.

Request finish samples to review tone and sheen under your lobby lighting. For specification support, share your element list, substrates, and performance context, and we will recommend a buildable path across MetaliQ, TruMetal, traditional metal finishing, or LuxCoat.

WhatsApp us